With the development of science and technology, today’s printing technology is also becoming more mature and developing rapidly. The printing process and production methods are becoming more and more abundant. The post-processing of “post-printing” refers to the post-printing work, including many processing methods, such as laminating, UV, hot stamping, hot stamping, mounting, binding, cutting, etc. It is also for publicity, commemorative albums, and packaging. printed matter.

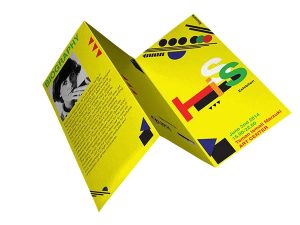

Hot stamping/hot silver

The scientific name is hot press transfer printing, or hot transfer printing for short, commonly known as bronzing and silver bronzing. It is a method of hot stamping the metal foil on the printed matter with the help of a certain pressure and temperature, and there is also a cold pad printing.

Hot stamping features: it has metallic luster and magnificence, which makes the printed picture have a strong contrast.

Scope of application: suitable for very prominent text or logo, mostly used for samples, greeting cards, invitations, wall calendars, desk calendars, etc.

UV coating

It is ultraviolet glazing, and UV is abbreviation, which means that the ink can be dried and cured by ultraviolet radiation. UV is usually a silk screen printing process, and now there is also offset printing UV.

Embossing/ embossing/ embossing

The scientific name is imprinting. It is a process of forming a pattern by pressure to cause local changes to the substrate. The metal plate is corroded and becomes a pressing plate and a base plate for pressing. Divided into two kinds of cheap ordinary corroded version and expensive laser embossed version.

Die cutting

The die-cutting process is a forming process in which a special die-cutting knife is made according to the design requirements of the printed matter, and then the printed matter or other substrates are rolled into the desired shape or cut under the action of pressure.

Glitter/silver onion

Wrap a layer of glue on the paper, and then sprinkle gold and silver powder on the glue.

YO binding

Objects like springs are mostly plastic. They are generally used on the spine of wall calendars and notebooks to connect pages.

Glue/film

Lay a layer of transparent plastic film on the printed paper, including crystal film, light film and matte film. There are two kinds of spectroscopic film and dumb film.

Pinhole

It is needlework, which presses a semi-connected line into the paper, usually at the opening of the package.

Punch

Use the printer to punch holes in the paper according to the size.

Flocking

It is to apply a layer of glue to the paper, and then paste a layer of material similar to fluff to make the paper look and feel a little fluffy.